Search

en

Stainless steel lifting eye bolts are capable of withstanding heavy loads and are designed for critical lifting applications, providing reliable, safe support.

With up to 1,000 hours of salt spray resistance, these stainless lifting eye bolts ensure durability and stability in challenging conditions. Our stainless steel lifting eyes and steel lifting eye options offer exceptional performance, making them ideal for demanding environments.

| Name | Eye bolts | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 4.8 8.8 10.9 12.9 A2-70 A4-70 A4-80 |

| Size | M3-M50 | Surface finish | ZPHDGBLACKDacromet etc. |

| Length | 15-500 | Samples | Available |

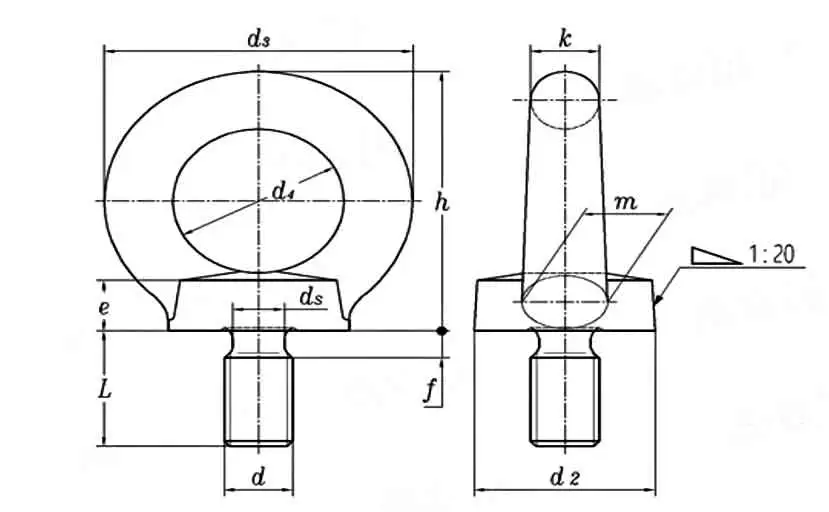

| Thread specification | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 | M56 | M64 | M72×6 | M80×6 | M100×6 | ||

| d | |||||||||||||||||

| d 2 | Nominal | 20 | 25 | 30 | 35 | 40 | 50 | 65 | 75 | 85 | 100 | 110 | 120 | 150 | 170 | 190 | |

| minimum | 19.5 | 24.5 | 29.5 | 34.5 | 39.3 | 49.3 | 64.3 | 74.3 | 84.2 | 99.1 | 108.9 | 118.8 | 148.7 | 168.5 | 188.5 | ||

| maximum value | 21.1 | 26.1 | 31.1 | 36.2 | 41.3 | 51.3 | 66.3 | 76.5 | 86.7 | 101.9 | 112.1 | 122.4 | 152.7 | 173 | 193 | ||

| d 3 | Nominal | 36 | 45 | 54 | 63 | 72 | 90 | 108 | 126 | 144 | 166 | 184 | 206 | 260 | 296 | 330 | |

| minimum | 35.4 | 44.4 | 53.4 | 62.4 | 71.3 | 89.3 | 107.3 | 125.2 | 143.1 | 164.8 | 182.8 | 204.7 | 258.3 | 294.3 | 328.3 | ||

| maximum value | 37.2 | 46.2 | 55.2 | 64.2 | 73.3 | 91.3 | 109.5 | 127.7 | 145.9 | 168.4 | 186.4 | 208.7 | 263.3 | 299.3 | 333.3 | ||

| d 4 | Nominal | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 140 | 160 | 180 | |

| minimum | 18.9 | 23.9 | 28.9 | 33.8 | 38.7 | 48.7 | 58.7 | 68.5 | 78.3 | 88.1 | 98.1 | 107.6 | 137.3 | 157.3 | 177 | ||

| maximum value | 20.5 | 25.5 | 30.5 | 35.6 | 40.7 | 50.7 | 60.7 | 70.7 | 80.8 | 90.9 | 100.9 | 111.2 | 141.3 | 161.3 | 181.5 | ||

| and | Nominal | 6 | 8 | 10 | 12 | 14 | 18 | twenty two | 26 | 30 | 35 | 38 | 42 | 50 | 55 | 60 | |

| minimum | 5.5 | 7.5 | 9.5 | 11.5 | 13.4 | 17.4 | 21.4 | 25.3 | 29.3 | 34.1 | 37.1 | 40.9 | 48.8 | 53.8 | 58.8 | ||

| maximum value | 7.1 | 9.1 | 11.1 | 13.1 | 15.2 | 19.2 | 23.2 | 27.3 | 31.5 | 36.9 | 39.9 | 44.1 | 52.4 | 57.4 | 62.4 | ||

| f | maximum value | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 12 | 12 | 12 | |

| ds | max = nominal | 6 | 7.7 | 9.4 | 13 | 16.4 | 19.6 | 25 | 30.3 | 35.6 | 41 | 48.3 | 55.7 | 63.7 | 71.7 | 91.7 | |

| minimum | 5.82 | 7.48 | 9.18 | 12.73 | 16.13 | 19.27 | 24.67 | 29.91 | 35.21 | 40.61 | 47.91 | 55.24 | 63.24 | 71.24 | 91.16 | ||

| h | Nominal | 36 | 45 | 53 | 62 | 71 | 90 | 109 | 128 | 147 | 168 | 187 | 208 | 260 | 298 | 330 | |

| minimum | 35.4 | 44.4 | 52.4 | 61.4 | 70.3 | 89.3 | 108.3 | 127.2 | 146.1 | 166.8 | 185.8 | 206.7 | 258.3 | 296.3 | 328.3 | ||

| maximum value | 37.2 | 46.2 | 54.2 | 63.2 | 72.3 | 91.3 | 110.5 | 129.7 | 148.9 | 168.4 | 189.4 | 210.7 | 263.3 | 301.3 | 333.3 | ||

| k | Nominal | 8 | 10 | 12 | 14 | 16 | 20 | twenty four | 28 | 32 | 38 | 42 | 48 | 60 | 68 | 75 | |

| minimum | 7.5 | 9.5 | 11.5 | 13.5 | 15.4 | 19.4 | 23.4 | 27.3 | 31.3 | 37.1 | 41.1 | 46.9 | 58.8 | 66.8 | 73.8 | ||

| maximum value | 9.1 | 11.1 | 13.1 | 15.1 | 17.2 | 21.2 | 25.2 | 29.3 | 33.5 | 39.9 | 43.9 | 50.1 | 62.4 | 70.4 | 77.4 | ||

| L | Nominal | 13 | 17 | 20.5 | 27 | 30 | 36 | 45 | 54 | 63 | 68 | 78 | 90 | 100 | 112 | 130 | |

| minimum | 12.71 | 16.71 | 20.15 | 26.65 | 29.58 | 35.5 | 44.5 | 53.5 | 62.5 | 67.5 | 77.4 | 89.4 | 99.4 | 111.3 | 129.2 | ||

| maximum value | 13.29 | 17.29 | 20.85 | 27.35 | 30.42 | 36.5 | 45.5 | 54.5 | 63.5 | 68.5 | 78.6 | 90.6 | 100.6 | 112.7 | 130.7 | ||

| m | Nominal | 10 | 12 | 14 | 16 | 19 | twenty four | 28 | 32 | 38 | 46 | 50 | 58 | 72 | 80 | 88 | |

| minimum | 9.5 | 11.5 | 13.5 | 15.5 | 18.4 | 23.4 | 27.4 | 31.3 | 37.2 | 45.1 | 49.1 | 56.9 | 70.8 | 78.8 | 86.8 | ||

| maximum value | 11.1 | 13.1 | 15.1 | 17.1 | 20.2 | 25.2 | 29.2 | 33.3 | 39.5 | 47.9 | 51.9 | 60.1 | 74.4 | 82.4 | 90.4 | ||

| Single weight (steel)≈kg | 0.06 | 0.11 | 0.18 | 0.28 | 0.45 | 0.74 | 1.66 | 2.65 | 4.03 | 6.38 | 8.8 | 12.4 | 23.3 | 34.2 | 49.1 | ||

Our stainless steel lifting eye bolts deliver high strength and up to 50% greater rust resistance than galvanized options, making them suitable for extreme environments. Built for secure load-bearing, each bolt is quality-tested for reliability in industrial and marine settings.

With easy installation and minimal maintenance, Befast’s eye bolts are a dependable choice for lifting applications. For projects demanding strength and corrosion resistance, trust Befast’s stainless steel solutions.