Search

en

(Covering DIN 934 standards, material selection, industrial use cases, and procurement strategies)

The DIN 934 hex nut is a cornerstone of fastener engineering, governed by Germany’s Deutsches Institut für Normung (DIN). This specification defines precise dimensions, mechanical properties, and tolerances for hexagonal nuts, ensuring uniformity across global manufacturing. Unlike region-specific standards, DIN 934 aligns with ISO 4032, making it universally compatible with metric bolts—from miniature M3 sizes in electronics to heavy-duty M64 variants in structural engineering. Its adoption spans aerospace, automotive, and construction, underpinning safety-critical assemblies where consistency is non-negotiable.

DIN 934’s rigorous dimensional criteria eliminate compatibility risks:

Dimensions:

Width Across Flats (A): Dictates wrench size (e.g., M8 nut: A=13mm; M24 nut: A=36mm).

Thickness (H): Balances strength and space efficiency (e.g., M12 nut: H=10.8mm).

Thread Pitch: Coarse threads (standard) for rapid assembly; fine threads for vibration resistance.

Tolerances: ±0.1mm–0.5mm variations ensure bolts thread smoothly without cross-binding.

Size Range: Covers M1.6 to M100, accommodating applications from watchmaking to bridge construction.

Example: An M20 DIN 934 hex nut has a 30mm width across flats, 18mm thickness, and 2.5mm pitch—optimized for structural steel connections.

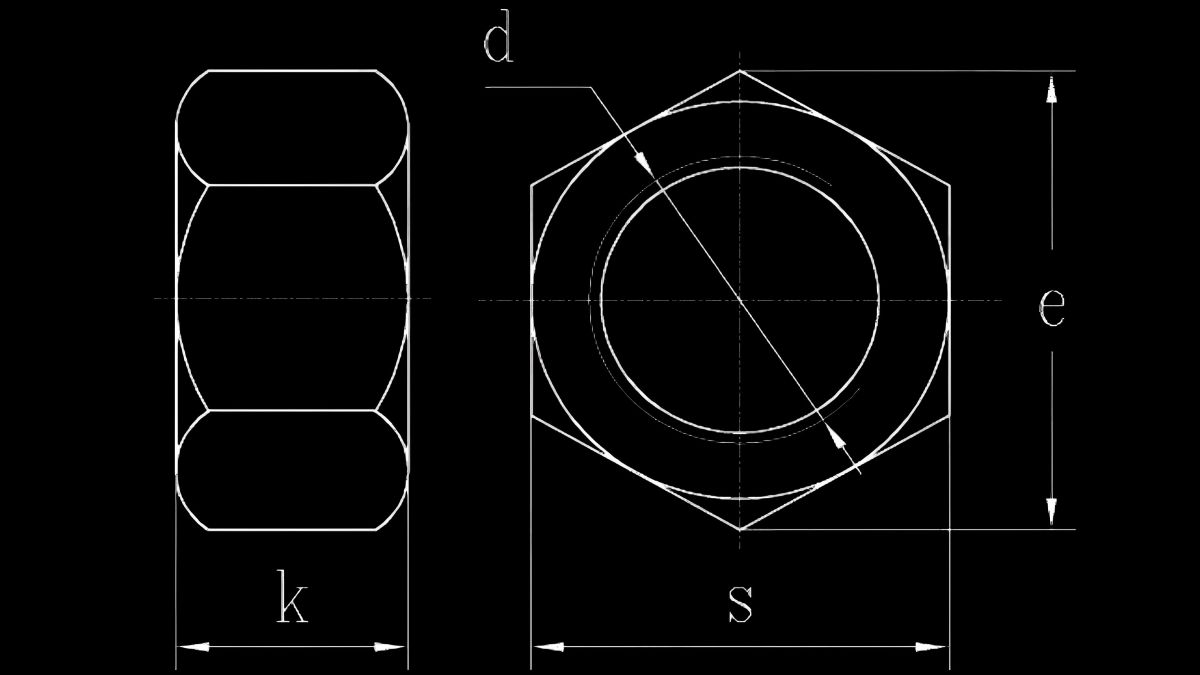

Technical drawings and dimensional tables are indispensable tools for engineers, procurement specialists, and quality controllers working with DIN 934 hex nuts. This section decodes standardized schematics to clarify critical design features and simplify specification matching.

3.1. Decoding the Standard Schematic

The DIN 934 schematic exemplifies German engineering precision, defining every geometry-critical element:

· Hexagonal Profile: 30° chamfered edges (reduces stress concentration at bolt junctions)

· Thread Engagement: Full 360° internal threading (class 6H tolerance per ISO 898-2)

· Key Annotations:

d = Nominal thread diameter (e.g., M6, M12)

s = Width across flats (determines wrench/spanner size)

m = Nut thickness (height) – impacts load distribution

e = Diagonal width across corners (used in confined spaces)

3.2. Critical Reference Tables for Design & Procurement

【插入附件中的表格】

While detailed numerical data exists in your tables, highlight these practical takeaways:

· Size Interdependencies: For an M10 nut (d=10mm), dimensions MUST align to:

o s = 17mm (ISO wrench compatibility)

o m = 8.4mm (ensures thread engagement strength)

· Tolerance Thresholds:

o d ≤16mm: Allowed ±0.1mm deviation

o d >16mm: ±0.5mm variation permissible

· Exception Handling:

o Thin-series nuts (DIN 439) reduce "m" height by 25%

o Jam nuts (DIN 936) have 50% lower "m"

3.3. Practical Applications of Diagrams & Tables

· Avoid Assembly Failures: Matching schematic angles prevents misalignment with DIN 931 bolts.

· Quality Verification: Measure "s" and "m" against tables to detect substandard counterfeits.

· Global Sourcing Efficiency: Quote exact parameters to suppliers (e.g., “DIN 934 M12, s=19mm, m=10.8mm, Grade 8”).

⚠️ Pro Tip: Cross-reference schematic "e" (corner width) values against your table. When using deep sockets, exceeding "e" causes tool slippage and stripped edges.

3.4. Technical Support & Product Sourcing

For project-specific schematics or dimension validation:

Download DIN 934 CAD Files & Full Spec Sheets

Request Custom Table Extracts: Need M4-M20 DIN 934 hex nut parameters? Email our engineers with size ranges.

Material choice directly impacts performance in corrosive, high-load, or extreme-temperature environments:

Material | Grades/Classes | Tensile Strength | Best For |

Carbon Steel | 4.6, 8.8, 10.9 | 400–1,000 MPa | General machinery, cost-sensitive projects |

Stainless Steel | A2-70, A4-80 | 700–800 MPa | Marine, chemical plants (resists pitting/crevice corrosion) |

Brass | CW614N | 250–400 MPa | Plumbing, electrical (non-sparking, conductive) |

Nylon | PA6, PA66 | 80–90 MPa | Lightweight assemblies, corrosion-free electronics |

Surface Treatments: Zinc plating (5–15µm) for basic corrosion resistance; hot-dip galvanizing (>50µm) for outdoor infrastructure; black oxide for aesthetic consistency.

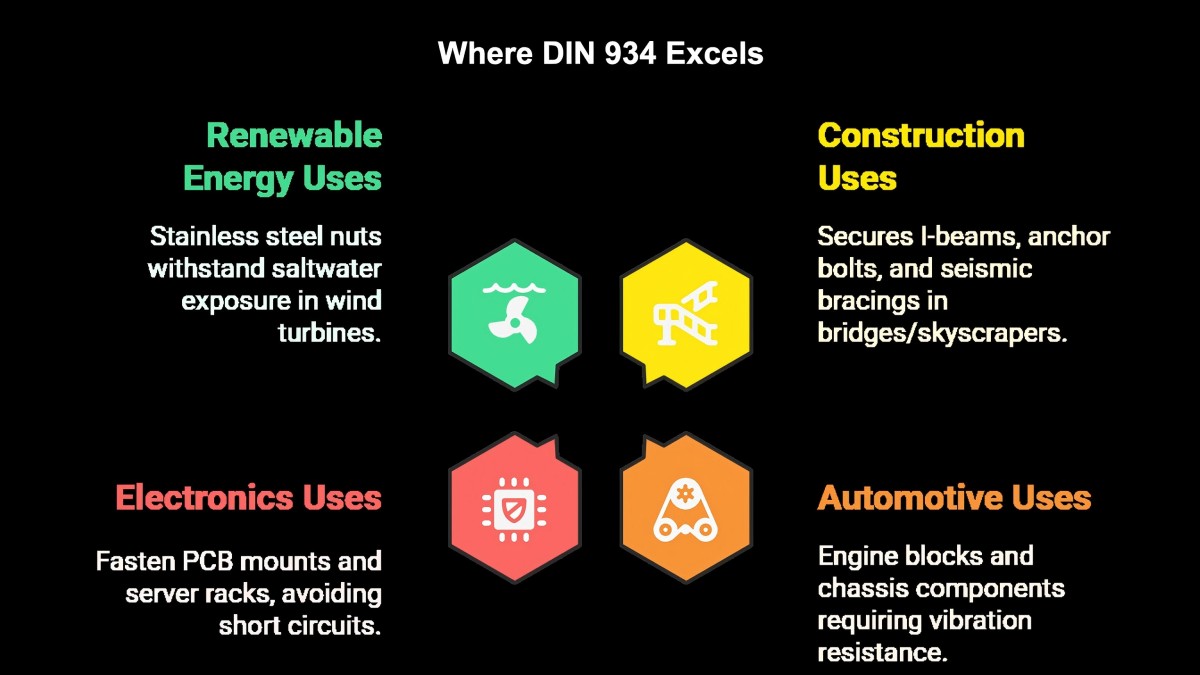

Construction: Secures I-beams, anchor bolts, and seismic bracings in bridges/skyscrapers.

Automotive: Engine blocks (M8–M14 nuts), chassis components (grade 10.9 for vibration resistance).

Electronics: M3–M5 nuts fasten PCB mounts and server racks (non-conductive nylon avoids short circuits).

Renewable Energy: Stainless steel (A4-80) nuts in offshore wind turbine assemblies withstand saltwater exposure.

Case Study: German automotive manufacturers mandate DIN 934 stainless steel nuts (A2-70) for exhaust systems—surviving 1,000°C temperatures and road salt.

Interchangeability: Identical dimensions across suppliers simplify replacements.

Load Distribution: 30° chamfered edges reduce bolt stress concentration, preventing shear failure.

Vibration Resistance: Precision threads + nylon insert options deter loosening in dynamic loads.

Cost Efficiency: Standardization cuts procurement time; bulk pricing at Chinbe Fastener starts at $0.02/unit (M6 carbon steel).

1. Match Bolt Grade: Pair Class 8.8 nuts with 8.8 bolts to prevent thread stripping.

2. Environment: Saltwater = A4 stainless; chemicals = epoxy coating; UV exposure = black oxide.

3. Certifications: Demand test reports (ISO 898-2 compliance for mechanical properties).

4. Supplier Audits: Verify manufacturing controls—cold-forged nuts offer superior grain structure vs. machined.

⚠️ Critical Tip: Avoid “DIN-like” uncertified nuts—substandard alloys may fracture under torque loads.

Leading DIN 934 producers combine material integrity with precision tooling:

Bhavya Industries (India): Specializes in M5–M24 nuts for mining equipment (Grade 10 strength).

Bharti Enterprise (India): Brass nuts for architectural fittings (BS2874-compliant).

ChinBefast (China): Carbon steel M2–M56 nuts with zinc/galvanized options (ideal for EU machinery exports).

DIN 934 hex nuts exemplify engineering pragmatism: standardized yet adaptable, robust yet economical. For projects demanding zero tolerance for failure—whether securing a turbine blade at sea or an automotive transmission—this standard guarantees peace of mind. As global industries converge on metric fastener systems, DIN 934 remains the benchmark for reliability.

Browse ChinBefast’s DIN 934 hex nut inventory, featuring:

15+ material/coating combinations

Full traceability with mill test certificates

Custom bulk packaging (1000kg+ MOQ)

Visit Product Page: DIN 934 Hex Nuts Collection

Limited-Time Offer: Request a free sample kit (5 sizes + material swatches) via our website inquiry form. Include project specs for volume discounts!

References & Further Reading:

Have torque specs or corrosion concerns? Our engineers respond to all inquiries within 4 hours. Submit a Request